TLZ three-column automatic industrial dehydrator

Product information

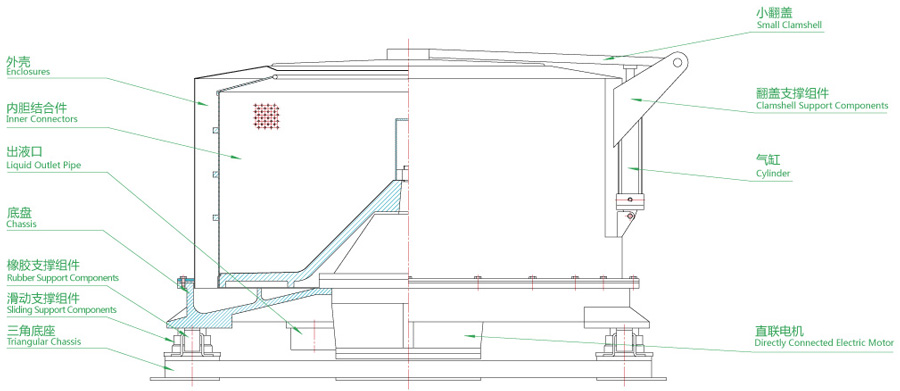

TLZ three-column automatic industrial dehydrator is an improved one of the SS three-column dehydrators. It abolishes the spring shock absorptance technology used in the traditional three-column centrifuges, and adopts the spherical vibration reduction technology combined with the mechanical and hydraulic pressure, and achieves a much better effect of shock absorption; It cancels the motor side hanging way used in the traditional centrifuges, and adopts directly connected motor. The rotary drum is driven by the directly connected motor, thus it not only improves the efficiency but also reduces the space of installation and operation;

This type dehydrators has large volume and higher automatic degree , and it is convenient to operate, so it is widely used in various fabric industries such as pulp, bleaching, dyeing, printing and washing.

Main features

1、Frequency conversion control system,start smoothly,separating factors can be adjusted;

2、It adopts the spherical vibration reduction technology combined with the mechanical and hydraulic pressure, and achieves a much better effect of shock absorption;

3、It adopts the directly connected electric motor to drive the rotary drum and has a high operation efficiency;

4、It adopts non-mechanical braking device, and brakes smoothly without wear and tear. It is also convenient for maintenance;

5、The inner container is designed into a large volume one on purpose, so it can load more and has a higher dehydrating efficiency ;

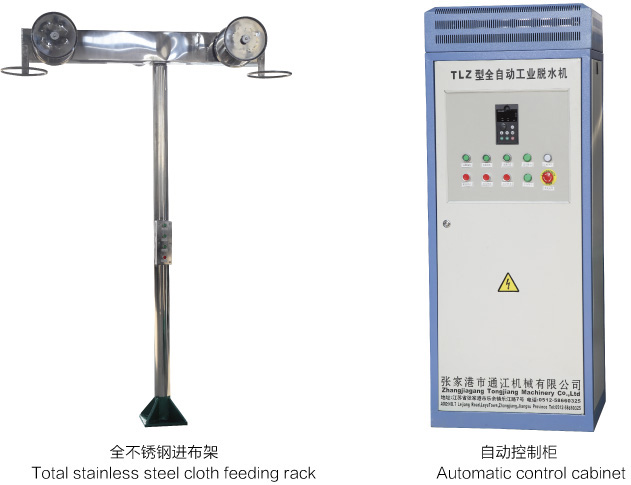

6、It is equipped with automatic cloth feeding device, improves the automatic degree and is convenient for operation;

Assembly

1、Frequency conversion control system and non-contact braking system;

2、The cylinder opening device;

3、Total stainless steel cloth feeding rack.

Optional assembly

1、Protection device for opening the large clamshells;

2、Protection device for over shock;

Techinical Parameters

| Model | Basket | Separation factors DW2/2g | Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

||

| Dia mm | Volume L |

Load limit Kg Max.charge |

|||||

| TLZ1500N | 1500 | 0-700 | 600 | 412 | 12 | 3000 | 2550×2200×2800 |

| TLZ1800N | 1800 | 0-520 | 900 | 273 | 15 | 4200 | 2865×2400×3000 |

| TLZ2000N | 2000 | 0-400 | 1100 | 180 | 18.5 | 5100 | 3100×2600×3300 |