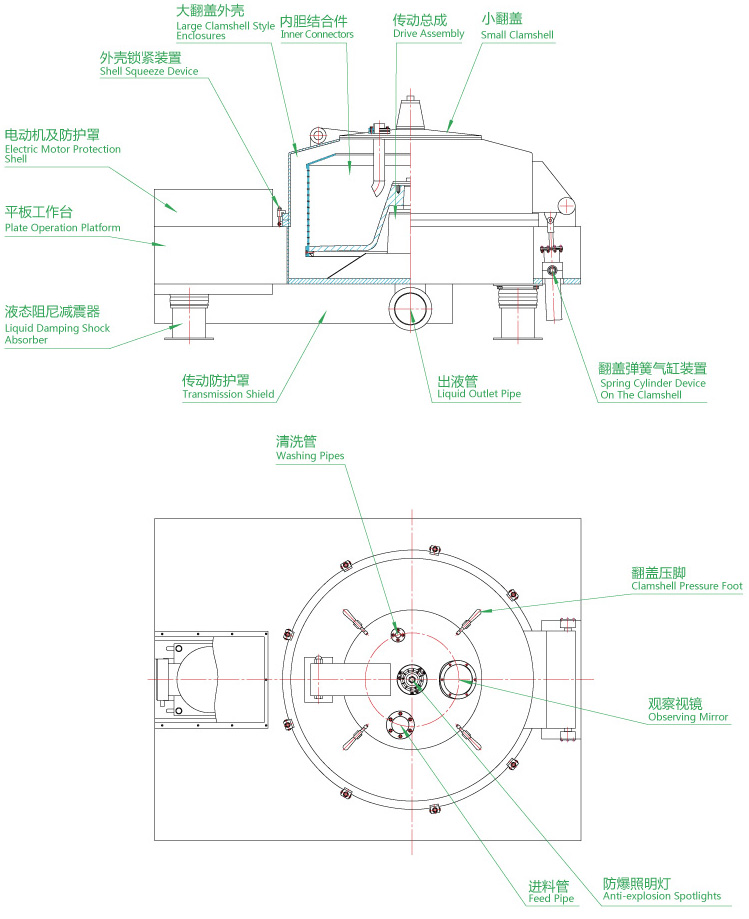

PQSB platform whole clamshell centrifuge

Main features

1、Whole clamshell structure, smooth constructure transition, polished surface, thus it is effective to eliminate the health blind corner. The external components, fasteners, and rotary drums are made of stainless steel, so the enclosure, rotary drums and the liquid outlet tank can be cleaned and washed thoroughly;

2、Frequency conversion control system,start smoothly,separating factors can be adjusted;

3、It has a high universality, and the crystals are not easily broken. It can be used in a wide range;

4、The engine base is a platform structure, it lowers the gravity center of the machine and makes operation more easier;

5、The enclosure is equipped with a small clamshell, and there are feed pipe, washing pipe, observing mirror and explosion-proof spot light on it;

6、It is equipped with liquid damping shock absorber, so it has a good effect of shock absorbance and simplifies the daily maintenance;

7、The sealing parts are made of silicon rubber or fluorine rubber, so it can meet the needs of sealing and explosion-proof, and it is used in toxic, inflammable and/or explosive situation;

8、Optional online cleaning devices are used to clean the centrifuge enclosure walls, the internal and external surfaces of the rotary drums, the surfaces of the liquid collecting tanks and other invisible parts of the centrifuges, thus they ensure to meet the requirement of cleanliness and fit into the GPM criterion;

Assembly

1、It is equipped with a whole clamshell enclosure, on the enclosure there is a small clamshell with an explosion-proof spot light, a feed pipe, a washing pipe and an observing mirror.

2、Ordinary electric motors or anti-explosion electric motors;

3、Frequency conversion control system and non-contact braking system;

4、Equipped with liquid damping shock absorber;

Optional assembly

1、Nitrogen protection devices;

2、Protection device for over shock;

3、Online cleaning devices;

4、Explosion-proof button;

5、The relevant building materials are selected according to the erosion-proof requirements of the materials to be processed: stainless steel 304, 316, 316L and 321, etc. Titanium materials or carbon steel with plastic, rubber or Halar inset on the surface.

Technical parameter

| Model | Basket | Separation factors DW2/2g | Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

|||

| Dia mm | Volume L | Load limit Kg Max.charge |

Speed r/min | |||||

| PQSB600 | 600 | 40 | 60 | 1350 | 612 | 3 | 1100 | 1500×1000×950 |

| PQSB8000 | 800 | 90 | 140 | 1200 | 645 | 5.5 | 1800 | 1900×1200×1000 |

| PQSB1000 | 1000 | 150 | 180 | 1000 | 560 | 7.5 | 2500 | 2100×1400×1100 |

| PQSB1200 | 1200 | 230 | 240 | 900 | 544 | 11/15 | 3400 | 2500×1700×1500 |

| PQSB1250 | 1250 | 280 | 350 | 900 | 567 | 15/18.5 | 3500 | 2500×1700×1150 |