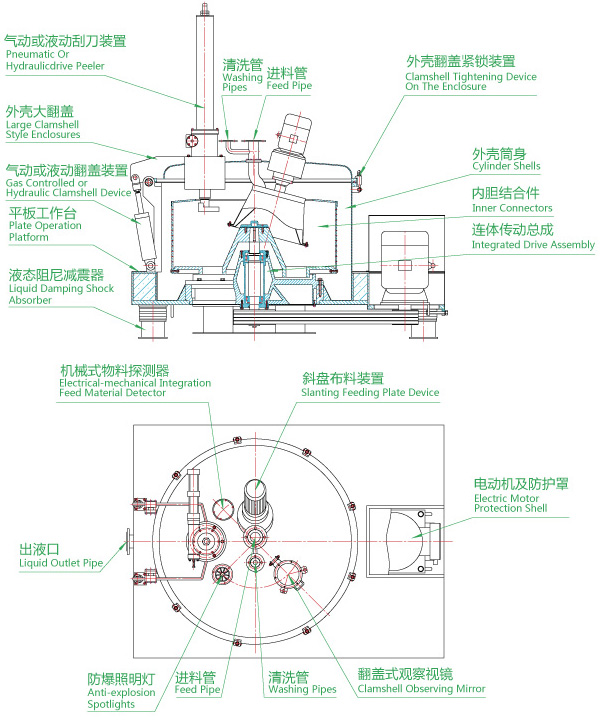

LGZ platform large clamshell automatic peeler discharging centrifuge

Main features

1、Frequency conversion control system,start smoothly,separating factors can be adjusted;

2、Controlled by PLC, after the program is set, the whole process of filling feed materials, pre-filtration, washing, fine filtration and discharging all can be controlled automatically;

3、The engine base and the enclosure are overall welded, so it has a larger load-carrying properties;

4、The engine base is a platform structure, so it not only lowers the gravity center of the machine,makes the machine works more smoothly, but also acts as an operation platform and makes operation more easier;

5、Isolated slanting feeding plate device: the feed materials can be well-distributed and it is also easier to operate, because it is connected with electrical control system, it can be controlled automatically;

6、It is designed into large clamshell, so it is much easier for the maintenance of the machine and the renewal of the filter cloth;

7、It is equipped with high viscosity liquid damping shock absorber, thus it can eliminate vibration more effectively, and simplify daily maintenance;

8、Seal structure, it is sealed by silicon rubber or fluorine rubber, so it can prevent some toxic, strong erosion feed materials leaking out or hurting people. It is of a high safety factor;

9、It adapts the electrical and mechanical integration style detector, and is of good reliability;

10、It adapts energy consumption braking, and non-contact braking methods, without friction or dust pollution;

11、Safety protection: Protection device for opening the large clamshells、Protection device for over shock、The machine is protected from over heat and over load, the rotation of the peeler and the elevator are controlled by both electrically and mechanically. The peeler and the rotary drums are in chain protection;

12、Optional nitrogen protection device, used in explosive situation;

Pneumatic or hydraulic drive clamshell device, clamshell tightening device on the enclosure, slanting feeding plate device, clamshell observing mirror

Assembly

1、The enclosure is designed into large clamshell, and it is equipped with peeler device, slanting feeding plate device, explosion-proof device, observing mirror, feed pipe and washing pipe;

2、Ordinary electric motors or anti-explosion electric motors;

3、Equipped with PLC frequency conversion control system and non-contact braking system;

4、Equipped with hydraulic station;

5、Equipped with electrical-mechanical integration feed material detector;

6、Equipped with liquid damping shock absorber;

Optional assembly

1、Nitrogen protection devices;

2、Protection device for over shock;

3、Online cleaning devices;

4、Gas auxiliary peeler;

5、Protection device for opening the large clamshells;

6、High pressure gas recoil device;

7、The discharging outlet is equipped with Pneumatic or hydraulic drive butterfly valve ;

8、The feed pipe and the washing pipe are equipped with Pneumatic or hydraulic drive ball valve;

9、Explosion-proof operation case;

10、The relevant building materials are selected according to the erosion-proof requirements of the materials to be processed: stainless steel 304, 316, 316L and 321, etc. Titanium materials or carbon steel with plastic, rubber or Halar inset on the surface.

Technical parameter

| Model | Basket | Separation factors DW2/2g | Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

|||

| Dia mm | Volume L | Load limit Kg Max.charge |

Speed r/min | |||||

| LGZ800 | 800 | 90 | 140 | 1200 | 645 | 7.5 | 2200 | 1800×1200×2050 |

| LGZ1000 | 1000 | 160 | 200 | 1000 | 560 | 11 | 3100 | 2000×1400×2250 |

| LGZ1200 | 1200 | 260 | 330 | 900 | 544 | 18.5 | 4500 | 2400×1800×2500 |

| LGZ1250 | 1250 | 300 | 400 | 900 | 567 | 22 | 4800 | 2400×1800×2500 |

| LGZ1500 | 1500 | 540 | 680 | 800 | 538 | 30 | 7000 | 2600×2200×2750 |