PX platform bottom discharging centrifuge

Main features

1、Frequency conversion control system,start smoothly,separating factors can be adjusted;

2、Simple in structure, convenient for cooperation, and the process of feeding materials, pre-filtration, washing and fine filtration can be adjusted at any accordingly;

3、Material crystals are not easy broken and it has a strong adaptability;

4、Manual bottom discharging, it can reduce the intensity of work and improve production efficiency;

5、The engine base is a platform structure, so it not only lowers the gravity center of the machine,makes the machine works more smoothly, but also acts as an operation platform and makes operation more easier;

6、It is equipped with high viscosity liquid damping shock absorber, thus it can eliminate vibration more effectively, and simplify daily maintenance;

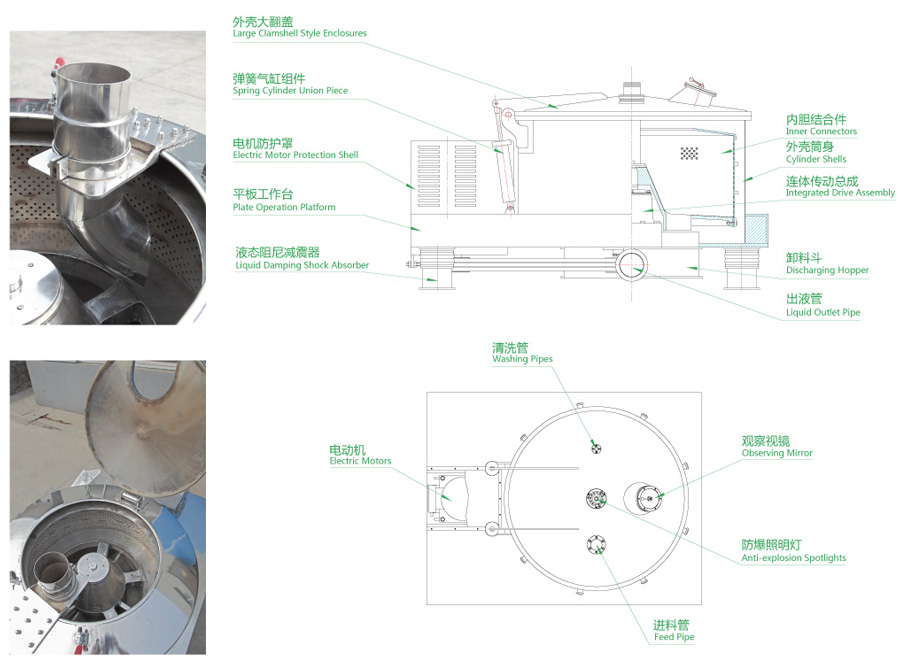

Assembly

1.Open-designed enclosures;

2.Ordinary electric motors or anti-explosion electric motors;

3.Frequency conversion control system and non-contact braking system;

4.Equipped with liquid damping shock absorber;

Optional assembly

1.Small clamshells,anti-explosion spotlights, feed pipes, dip pipes, observing mirrors;

2. Protection device for over shock;

3. Explosion-proof button;

4.The relevant building materials are selected according to the erosion-proof requirements of the materials to be processed: stainless steel 304, 316, 316L and 321, etc. Titanium materials or carbon steel with plastic, rubber or Halar inset on the surface.

Technical parameter

| Model | Basket |

Separation factors DW2/2g |

Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

|||

| Dia mm | Volume L | Load limit Kg Max.charge |

Speed r/min | |||||

| PX800 | 800 | 90 | 140 | 1200 | 645 | 5.5 | 1800 | 1800×1200×950 |

| PX1000 | 1000 | 160 | 200 | 1000 | 560 | 7.5 | 2800 | 2000×1400×1000 |

| PX1200 | 1200 | 260 | 330 | 900 | 544 | 11 | 3400 | 2400×1700×1350 |

| PX1250 | 1250 | 300 | 400 | 900 | 567 | 15 | 3600 | 2400×1700×1350 |