Flat structure pull-bag scraper discharge centrifuge

Product Features

1. Adopting frequency conversion control, smooth start-up, adjustable separation factor;

2. Adopting PLC control and program setting, the entire process of feeding, initial filtration, washing, fine filtration, unloading, and filter cloth regeneration (removing residual filter cake) is automatically controlled. All processes can run according to the pre-set program according to customer requirements;

3. The transition of the structural components of the whole machine is smooth and flat, effectively eliminating hygiene blind spots; The flip cover adopts a butterfly shaped flip cover structure, which has good rigidity and strength;

4. The feeding adopts an independent inclined disc feeding method, with adjustable feeding speed. The feeding speed is asynchronous with the drum speed, especially for crystals with good dewatering performance and large particle size, which can reduce or eliminate the vibration caused by uneven feeding.

5. The platform style four point support vibration reduction system adopts high viscosity liquid damping dampers and large inertia balance plates, with excellent vibration reduction effect.

6. The large flip structure design makes machine maintenance and filter cloth replacement more convenient.

7. Sealed structure, with sealing components made of silicone rubber or fluororubber, can prevent toxic and highly corrosive materials from leaking and injuring people, with a high safety factor;

8. Adopting an electromechanical integrated material detector with good reliability;

9. Energy consumption braking, non-contact braking method, no friction dust pollution;

10. Safety protection: lid opening protection, over vibration protection device, air pressure protection device, motor overload protection

Thermal protection device, scraper rotation (lifting) mechanical and electrical dual control.

11. Configure residual filter cake removal device: After scraping the material with a scraper, use a cylinder to remove residual filter cake by pulling the filter bag to avoid secondary pollution.

12. Adopting self-locking reliable and convenient filter bag fixing method, it can quickly complete filter bag replacement

Standard configuration:

1. The shell is designed with a large flip cover, equipped with a scraper device, inclined plate fabric device, explosion-proof lighting, quick opening manhole, feeding pipe, and washing pipe;

2. Configure ordinary motors or explosion-proof motors;

3. Configure the frequency conversion control system and non-contact braking system of the PLC device;

4. Configure pneumatic control station and hydraulic control station;

5. Configure electromechanical integrated material detector;

Optional configuration:

1. Nitrogen protection device;

2. Overvibration protection device;

3. Online cleaning device;

4. Gas assisted scraper device;

5. Open cover protection device;

6. High pressure gas recoil device;

7. Unloading pneumatic or hydraulic butterfly valve;

8. Select the corresponding materials according to the anti-corrosion requirements of the separated materials: stainless steel 304, 316, 316L, 321, etc., titanium or carbon steel surface lining with plastic, rubber, and Halar.

Scope of application

This centrifuge is not only suitable for solid-liquid separation of general media, but also for solid-liquid separation of media with poor fluidity and poor fabric performance. It has good adaptability to materials and is suitable for industries such as pharmaceuticals, food, and chemicals.

Product parameters

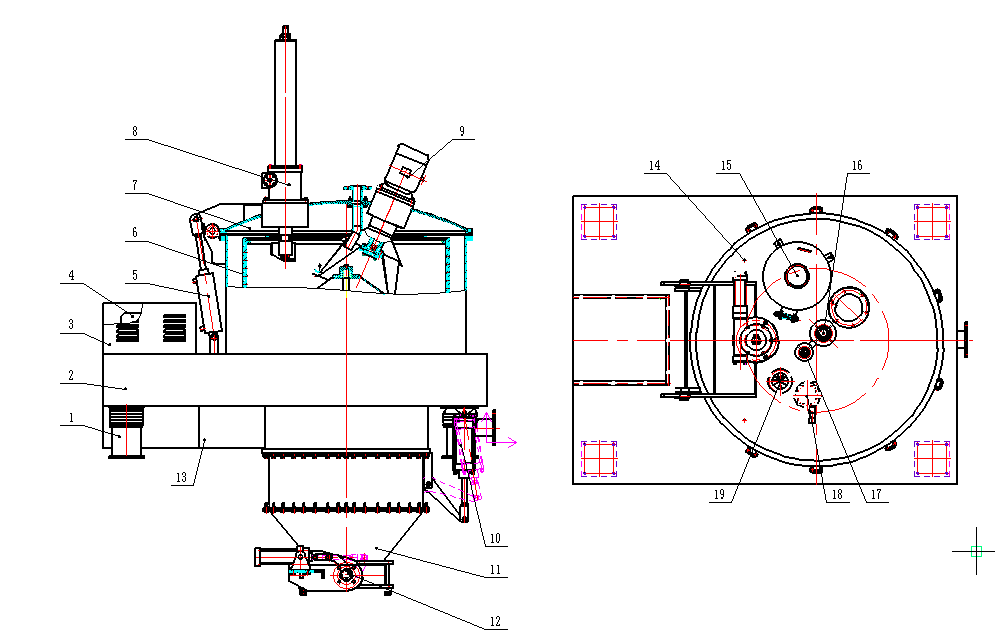

1. Liquid damping shock absorber 2. Flat component 3. Motor cover 4. Power component 5. Open cover oil cylinder 6. Inner container component 7. Upper cover component 8. Scraper component 9. Fabric motor component 10. Unloading rack lifting component 11. Aggregate hopper 12. Unloading butterfly valve 13. Belt cover 14. Nitrogen interface 15. Manhole mirror 16. Feeding pipe 17. Cleaning pipe 18. Material level detector 19. LED explosion-proof lighting

|

Project |

Model |

||||

|

LLGZ1200 |

LLGZ1250 |

LLGZ1400 |

LLGZ1500 |

LLGZ1600 |

|

|

Inner diameter of drum mm |

1200 |

1250 |

1400 |

1500 |

1600 |

|

Effective height of drum mm |

455 |

615 |

720 |

710 |

750 |

|

Diameter of liquid blocking plate mm |

900 |

900 |

1000 |

1100 |

1100 |

|

Drum capacity L |

250 |

400 |

600 |

650 |

850 |

|

Filter area m2 |

1.71 |

2.4 |

3.2 |

3.34 |

3.8 |

|

Maximum loading limit kg |

325 |

520 |

600 |

845 |

1105 |

|

Drum speed r/min |

1000 |

1000/1200 |

945 |

850 |

850 |

|

Separation factor |

673 |

700/1006 |

700 |

609 |

648 |

|

Motor power Kw |

18.5 |

22 |

30 |

30 |

45 |

|

Dimensions (length, width, height)mm |

2400*1800*2360 |

2400*1800*2770 |

2600*2000*3050 |

3000*2400*3055 |

3000*2400*3225 |

|

Machine weight kg |

≈4800 |

≈6500 |

≈7800 |

≈11500 |

≈12500 |