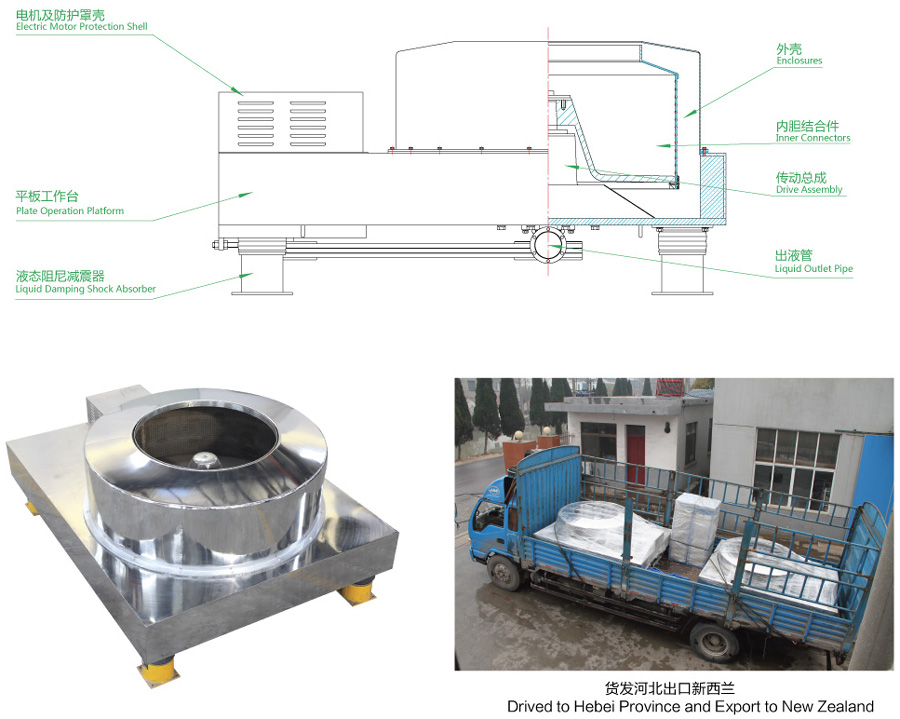

PS platform dehydrator

Main features

1、Frequency conversion control system,start smoothly,separating factors can be adjusted;

2、It is equipped with non-contact braking system, and it is convenient for maintenance;

3、The inner container is designed into a large volume one on purpose, it has a higher dehydrating efficiency during a single work time.

4、Considering the special circumstances about the feather product processing industry, the inner container is designed into a small bore;

5、The liquid blocking board of the inner container is reasonably designed to prevent the materials from entering the seams between the inner container and the enclosure;

6、The engine base is a platform structure,so it not only lowers the gravity center of the machine and makes the machine works more smoothly, but also acts as an operation platform and makes operation more easier;

7、It is equipped with liquid damping shock absorber, so it has a good effect of shock absorbance and simplifies the daily maintenance;

Standard configuration

1、Open-designed enclosures;

2、Equipped with ordinary single-speed or two-speed motor;

3、Equipped with mechanical up to brake or to hold the brake device;

Optional configuration

1、Equipped with a small clamshells or a large clamshells;

2、Protcetion device for over shork;

Techinical Parameters

| Model | Basket |

Separation factors DW2/2g |

Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

|||

| Dia mm | Volume L | Load limit Kg Max.charge |

Speed r/min | |||||

| PS800N | 800 | 100 | 120 | 1200 | 645 | 5.5 | 1500 | 1800×1200×1000 |

| PS1000N | 1000 | 150 | 180 | 1000 | 560 | 7.5 | 2200 | 2000×1400×1000 |

| PS1200N | 1200 | 260 | 290 | 900 | 544 | 11 | 3500 | 2400×1700×1000 |

| PS1500N | 1500 | 540 | 400 | 700 | 412 | 15/18.5 | 4000 | 2500×2000×1150 |

| PS1600N | 1600 | 673 | 500 | 700 | 440 | 18.5 | 4100 | 2500×2000×1150 |

| PS1800N | 1800 | 960 | 600 | 520 | 273 | 22 | 4800 | 2900×2400×1200 |

| PS2000N | 2000 | 1150 | 720 | 400 | 180 | 30 | 5500 | 3000×2500×1250 |