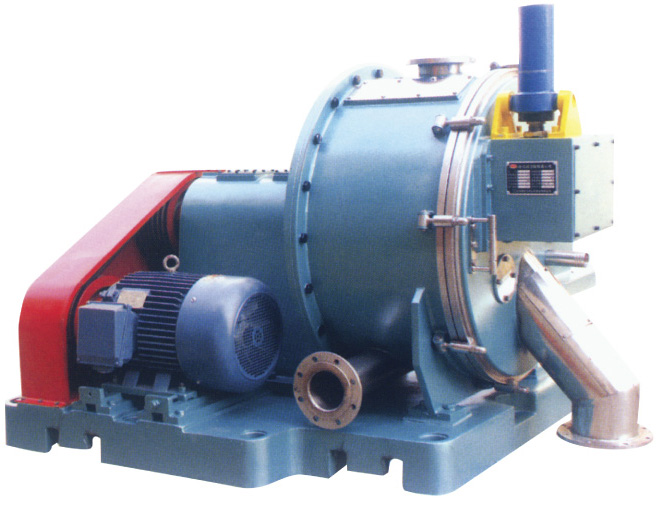

GK horizontal peeler discharging centrifuge

Main features

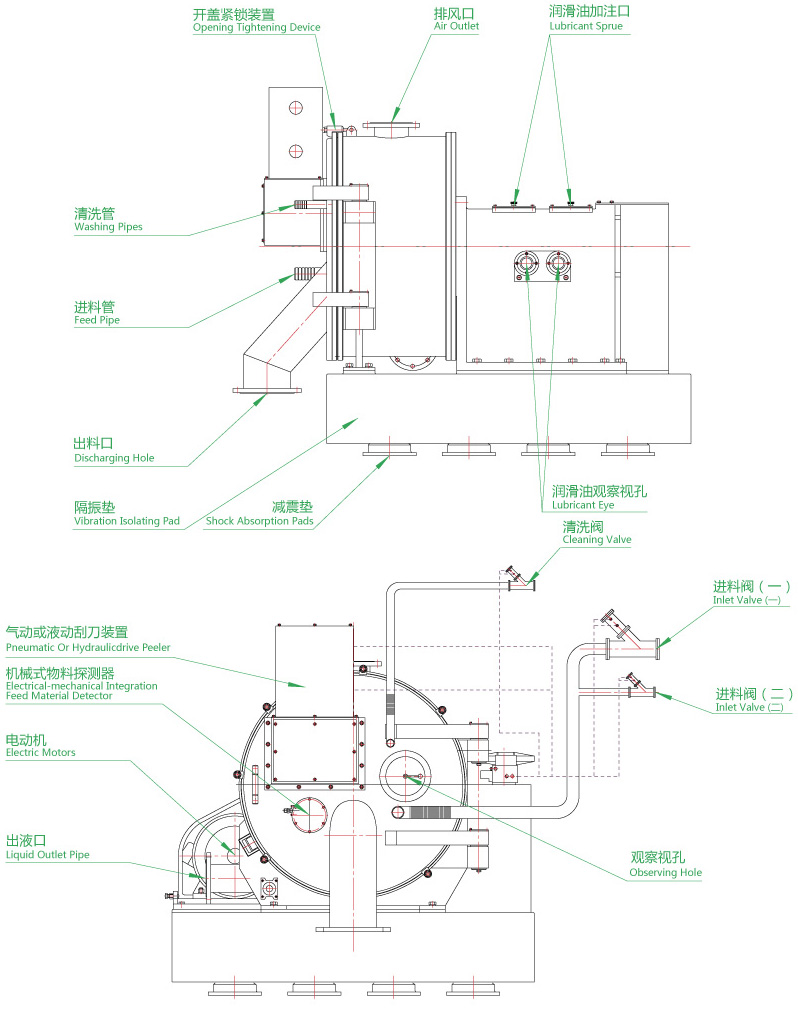

1、Frequency conversion control system,start smoothly,separating factors can be adjusted;

2、Controlled by PLC, after the program is set, the whole process of filling feed materials, pre-filtration, washing, fine filtration and discharging all can be controlled automatically;

3、The enclosure is a close welded structure, so it has a larger load carrying properties;

4、The electric motor and the host are in integral installation, it is convenient for installation and operation, and it can also reduce the occupied space;

5、Seal structure, it is sealed by silicon rubber or fluorine rubber, so it can prevent some toxic, strong erosion feed materials leaking out or hurting people. It is of a high safety factor;

6、It is equipped with an independent hydraulic station, and can be isolatedly installed, so it is easy for maintenance;

7、Safety protection: vibration protection system, motor overload and over heat protection, mechanical and electrical dual control about the peeler's revolution, promotion and demotion, peelers and rotary drums are in a chain protection;

8、It is equipped with vibration isolation and rubber vibration reduction devices, so the machine can work smoothly with much lower vibration and noises, and it can also improve the working conditions, reducing the harm caused to apparatus and environment by vibration;

9、The accessories and components of the inner parts contacting the materials and the outer parts as well as the fasteners are all made of stainless steel, so it can improve the erosion resistance of the apparatus;

10、Optional the spiral conveyor for discharging(GK1250-N and more advanced machines), it can prevent the materials from being blocked up for not slippy materials;

Working Principle

The horizontal scraper discharging centrifuge is a type of screen centrifuge that can work successively and can be operated in clearance operations. It is automatically controlled, and also can be controlled manually. Unlike the common vertical type centrifuges, the whole process of filling feed materials, separating, washing, dehydration, discharging and the renewal of the filter cloth is completed at a high speed when using this type of centrifuge. So it can process a large volume of materials during a short single work time, and much drier sludge and better washing effect can be achieved.

Technical parameter

| Model | Basket |

Separation factors DW2/2g |

Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

|||

| Dia mm | Volume L | Load limit Kg Max.charge |

Speed r/min | |||||

| GK800N | 800 | 80 | 120 | 1500 | 1008 | 30 | 5500 | 2500×1600×1800 |

| GK1000N | 1000 | 172 | 240 | 1350 | 1023 | 37 | 8500 | 2800×1800×2000 |

| GK1250N | 1250 | 340 | 425 | 1200 | 1008 | 55 | 130000 | 3820×2450×2100 |