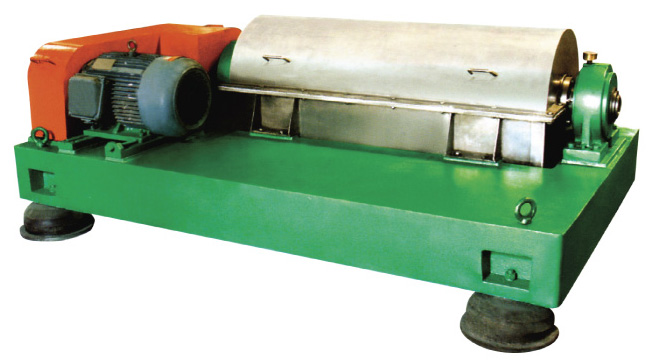

LW horizontal spiral discharging sedimenting centrifuge

Product Information

LW horizontal spiral discharging sedimenting centrifuge is a type of centrifuge that it separates suspension through centrifugal sedimentation, and discharges material by spiral conveyer blade. It can continuous feed, separation and discharge at full speed. It is suitable for suspension of float liquid whose fineness of solid-phase material is between 0.005mm and 2mm、whose concentration is between 2% and 40% to realizing solid liquid separation, particle size classification, liquid clarification and so on. It is especially suitable for the suspension that the filter fabric regeneration difficulties, concentration, particle size range is larger to separating.

Main features

1、The drum and scroll conveyor are made of stainless steel and titanium resisting corrosion.

2、The scroll conveyor was coated with wearable alloy or welded with alloy plate.

3、Stepless speed regulation for the bowl.

4、Step or stepless speed regulation for scroll’s differential speed.

5、Simple lubrication.

6、Safety protection system: rev test, over vibration and over load protection, scroll zero differential protection.

7、Optional the hydraulic differential gear, it is especially suitable for the highly sticky materials .

Applications

Separating and dewatering the industrial and domestic water;

Wash, classification and dewatering for amylum;

Dewatering for soybean, wheat;

Dewatering for fish meal, fish;

Dewatering for lees;

Classification for juice and dewatering for fruits;

Separation and purification for animal and vegetable oil;

Separation and purification for coal tar;

Classification and dewatering for kaolin and graphite;

Classification and dewatering for dyestuff and pigment;

Classification and dewatering for ore slurry;

Working Principle

Once the suspension enter the bowl, the solids is settled on the bowl wall under the centrifugal force, the settling particles is drived from the separation chamber ( cylinder chamber ) and drying chamber ( conical chamber ) to outlet, and the clarified liquid flows out from the hole. Thus the liquid and solids are separated continuously.

Technical parameter

| Model | Basket | Separation factors DW2/2g | Power of motor Kw | Weight Kg | Overall dimension (L×W×H) mm |

||

| Dia mm | Ratio of length diameter | Speed r/min | |||||

| LW220×660 | 220 | 3 | 4800 | 2838 | 7.5-11 | 900 | 1650×1150×700 |

| LW220×880 | 220 | 4 | 4300 | 2278 | 7.5-11 | 1000 | 1850×1200×750 |

| LW300×900 | 300 | 3 | 4000 | 2688 | 11-15 | 1200 | 2100×1400×900 |

| LW300×1140 | 300 | 3.8 | 3750 | 2363 | 11-15 | 1500 | 2400×1400×900 |

| LW350×1400 | 350 | 4 | 3700 | 2683 | 15-22 | 2100 | 3000×1050×1000 |

| LW400×1200 | 400 | 3 | 3500 | 2744 | 18.5-22 | 2500 | 2400×1650×950 |

| LW450×1440 | 450 | 3.2 | 3500 | 3087 | 22-30 | 2450 | 3100×2100×1200 |

| LW500×1600 | 500 | 3.2 | 3000 | 2520 | 30-37 | 3300 | 3000×1500×1050 |

| LW530×2000 | 530 | 3.8 | 3000 | 2671 | 37-45 | 3900 | 4800×1200×1350 |